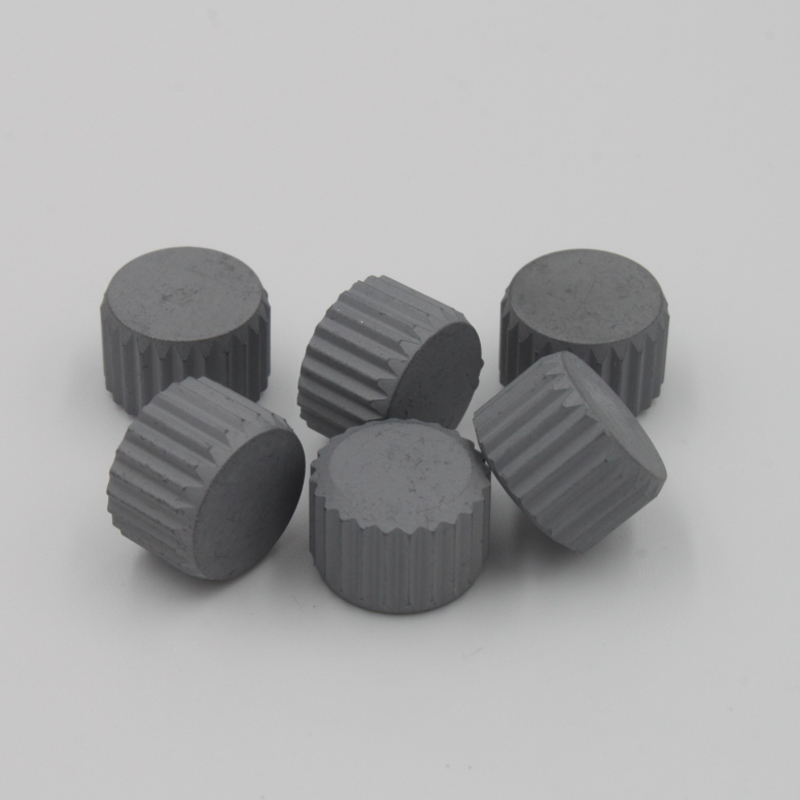

Tungsten Carbide Flattop Buttons Cemented Carbide Gauge Teeth

Tunsten carbide Grade we provided

| Grade | Cobalt% | Density(g/cm3) | HRA | TRS |

| BS10 |

6% |

14.8-15.0 |

90.1 |

2100 |

| BS20 |

8% |

14.6-14.8 |

90 |

2100 |

| BS15 |

8% |

14.6-14.8 |

88.5 |

2300 |

| BS25 |

9% |

14.5-14.7 |

88.1 |

2500 |

| BS45 |

11% |

14.2-14.4 |

87 |

2600 |

| BS40 |

15% |

13.9-14.1 |

87 |

2020 |

Tungsten Carbide is one of the hardest and most heat resistant alloys known until now. The tungsten carbide tools are reliable, long lasting, and resistant to day-to-day use damage in numerous industries includingmining, oil and gas drilling, road construction, metal tooling, tunneling or CNC machining.

Carbide buttons are mainly use for oil filed drilling, rock drilling, snow removal, water well drilling, or civil construction.

This serrrated flat carbide buttons is used to reduce wear on abrasive steel surfaces and in applications where less precision is required in hole drilling.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory, since 2010.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: Do you provid custom service?

A: Yes. We will make mould based on your drawings, and can send sample for test quality firstly.

Packing, Storage, Handling and Transportation