-

High quality tungsten carbide wire drawing

High quality tungsten carbide wire drawing High quality tungsten carbide wire drawing is typically used in the manufacturing of wire and cables. Tungsten carbide is known for its hardness and wear resistance, making it an excellent material for drawing wire through a die to reduce its diameter. This process is commonly used in the production of various types of wires such as electrical wires, welding wires, and steel wires. Tungsten carbide wire drawing dies are also used in the production of... -

Tungsten Carbide Scarifier Drum for Concrete Milling Machine

Tungsten Carbide Scarifier Drum for Concrete Milling Machine is a specialized attachment that is designed for use with concrete milling machines. It is made of tungsten carbide, which is a durable and wear-resistant material that can withstand the high demands of concrete milling. The scarifier drum has a unique design that allows it to remove concrete quickly and efficiently, leaving behind a smooth and even surface. This attachment is commonly used in construction and demolition projects where concrete surfaces need to be removed or modified.

-

Tungsten Carbide Spiral Rods with Two Holes

Tungsten Carbide Spiral Rods with Two Holes refer to a type of carbide rod that is made of tungsten carbide, which is a hard and durable material that is often used in industrial settings. These rods typically have a spiral shape and two holes, and are used in various applications such as cutting, drilling, and grinding. They are known for their long lifespan and high performance, especially in high temperature and high stress environments.

-

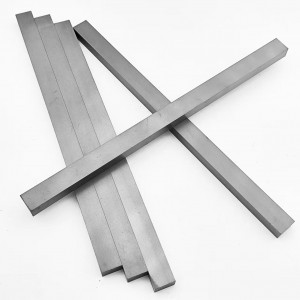

K10 Tungsten Carbide Strips

K10 High Strength Cemented Carbide Sheet Plate Strip

-

Tungsten Carbide Plates for Tamping Tools

Tungsten carbide plates for tamping tools are hard and durable plates made from a combination of tungsten and carbon. These plates are used in tamping tools, which are used for compacting soil, asphalt, or other materials. The tungsten carbide plates are designed to provide excellent wear resistance and long-lasting performance, making them ideal for heavy-duty tamping applications. They help to increase the efficiency and effectiveness of tamping tools by providing a strong and durable surface for compacting materials.

-

Two Ends Straight Tungsten Carbide Gripper Inserts

Two Ends Straight Tungsten Carbide Gripper Inserts are components used in machinery and equipment for gripping and holding materials in place. These inserts are typically made of tungsten carbide, a hard and durable material known for its resistance to wear and abrasion. The “two ends straight” descriptor may refer to the specific shape and design of the inserts, which are likely designed to provide a secure grip on materials. These inserts are commonly used in industries such as manufacturing, machining, and metalworking for securely holding workpieces during operation.

-

Tungsten Carbide Q Type Spherical Button

Tungsten Carbide Q Type Spherical Button is a type of mining tool used to crush and grind rocks. These buttons are made of tungsten carbide, a very hard and durable material, which makes it ideal for drilling and excavation in harsh conditions. The spherical shape of the button allows for better impact and wear resistance, making it an efficient and long-lasting tool for mining operations.

-

Carbide Brazed Tips for Lathe Cutting

Carbide brazed tips are cutting tools used in lathe machining. They are made of a hard substance called carbide, which is brazed or bonded to a steel shank. These tips are used for cutting, shaping, and finishing various materials such as metal, wood, and plastic. The carbide material provides superior hardness and wear resistance, making it suitable for high-speed machining and extended tool life. These tips are commonly used in lathe operations for precision and efficiency in metalworking and other machining processes.

-

Solid Tungsten Carbide Tips for Tamping Tines Tools

The tungsten carbide tip for tamping tools is a specially designed tool for tamping rock in railway line beds. The tip is made of cemented carbide, has high hardness and good wear resistance, and can withstand high-intensity tamping operations.

These tungsten carbide tips are usually used in conjunction with tamping picks and other tools to rearrange the roadbed stones by vibration or impact. Due to its high hardness and wear resistance, it can greatly improve the efficiency of tamping operation and reduce the time and cost of maintenance operation.

-

High Performance Tungsten Carbide Wear Parts

Cemented carbide wear-resistant parts have high hardness, strong wear-resistant performance, even in high temperature, high pressure, shock, vibration and other complex working conditions can also maintain high wear resistance and long service life. Therefore, it has a wide range of applications in many fields, such as iron and steel, mining, petroleum, chemical and other industries in mechanical equipment.

-

Tungsten Carbide Drilling Tools

Tungsten carbide drilling tools are cutting tools used for creating holes in materials such as metal, wood, plastic, and other hard substances. They are made from a compound of tungsten and carbon, known as tungsten carbide, which is very hard and wear-resistant. This makes tungsten carbide drilling tools suitable for drilling in challenging materials and for prolonged use. Tungsten carbide drilling tools are often used in industries such as construction, manufacturing, and mining, where precision drilling and durability are required.

-

Coating Highly Efficiency Tungsten Carbide Wire Drawing Dies

Tungsten carbide wire drawing dies are specialized tools used in the wire drawing process to reduce the diameter of wire while increasing its length. These dies are made of tungsten carbide, a high-performance material known for its hardness, wear resistance, and thermal conductivity. Tungsten carbide wire drawing dies are used in various industries, such as wire and cable manufacturing, to produce wires of different diameters for a wide range of applications. These dies are designed to withstand the high pressures and temperatures involved in the wire drawing process, and they help to produce high-quality wire with precise dimensions.