Properties of tungsten carbide rod and its applications Tungsten carbide or cemented carbide has many superb characteristics such as high hardness, good strength, good wear and corrosion resistance and salient stability under higher temperatures even at 500°C. It remains unchanged and even at 1000°C attains high hardness.

Cemented Tungsten Carbide rods is sintered in HIP Furnace and is made of 100% virgin raw material which is including WC and CO.

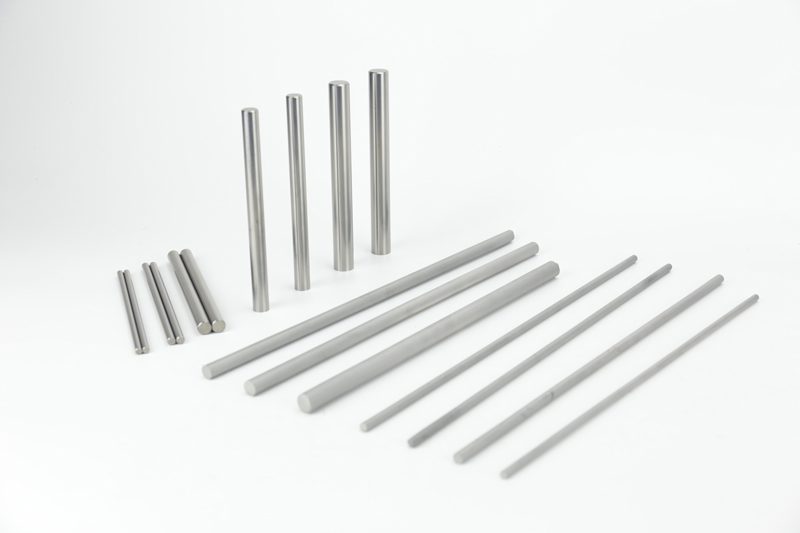

There are usually three types of cemented tungsten carbide rods such as PCB rod, blank rod, and rod.

The majority of its applications are in the production of cutting tools for metal, as well as for wood, plastics, and other materials and industries that need high levels of hardness, wear resistance, and corrosion resistance.

Tungsten carbide rod possesses a multitude of exceptional qualities, including high levels of hardness and strength, great resistance to wear and corrosion, and remarkable stability even when subjected to high temperatures. Cast iron, nonferrous metals, plastics, chemical fibre, stainless steel, and high manganese steel are just some of the materials that can be cut with this tool. Additionally, it can be used to make drilling tools, mining tools, wear parts, precision bearings, nozzles, and metal moulds, among other things.

Here are some steps of producing tungsten carbide rods.

1) Grade Design

Grade made by our factory: SK10, SK30, SK35B, SK35, SK45 etc.

Recommend the right Grade for the applications of tungsten carbide rods.

2) RTP Ball Milling

The ball grinding mill has the ability to manufacture powder of any grain size, including fine and ultra-fine powder from the combined material of the WC powder, cobalt powder, and doping materials.

Spray -Drying Process

In order to guarantee that the material is completely clean, the prilling tower is sprayed with drying spray.

3) Extrusion or Direct Pressing

2 different ways to produce the carbide rods.

4) Drying Process

5) Sintering

The blade undergoes a heat treatment at a temperature of 1500 degrees Celsius for a period of 15 hours.

6) Machining

Customer requiures H5/H6 ground surface, then we will process carbide rods with centerless grinding.

7) Quality Test and Inspection

To test the straightness, sizes, and physical performance like TRS, Hardness and carbide rods appearance etc.

8) Packaging

Pack carbide rods in Plastic box with label on it.

Post time: Mar-04-2023